Flood Lighting

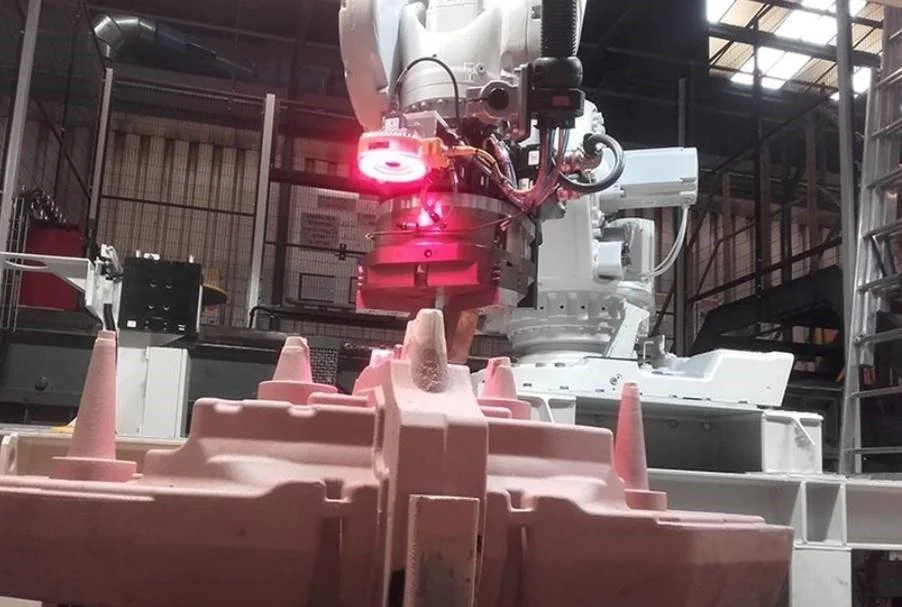

When you need to evenly illuminate a larger area and no specific direction, LWD, etc. is required because the target information itself already has high contrast. Applications for flood lighting focus on uniformity and intensity as the LWD tends to be longer.

Just “Making it Brighter” Rarely Solves the Problem

When you use flood lighting in a machine vision system, you’re usually solving one of two challenges: illuminating a large field of view (FOV) or lighting a target from a long working distance (LWD). Both scenarios demand high light output, but simply increasing brightness often creates new problems.

Because what often undermines the inspection performance isn’t too little light—it’s too much variation across the image.

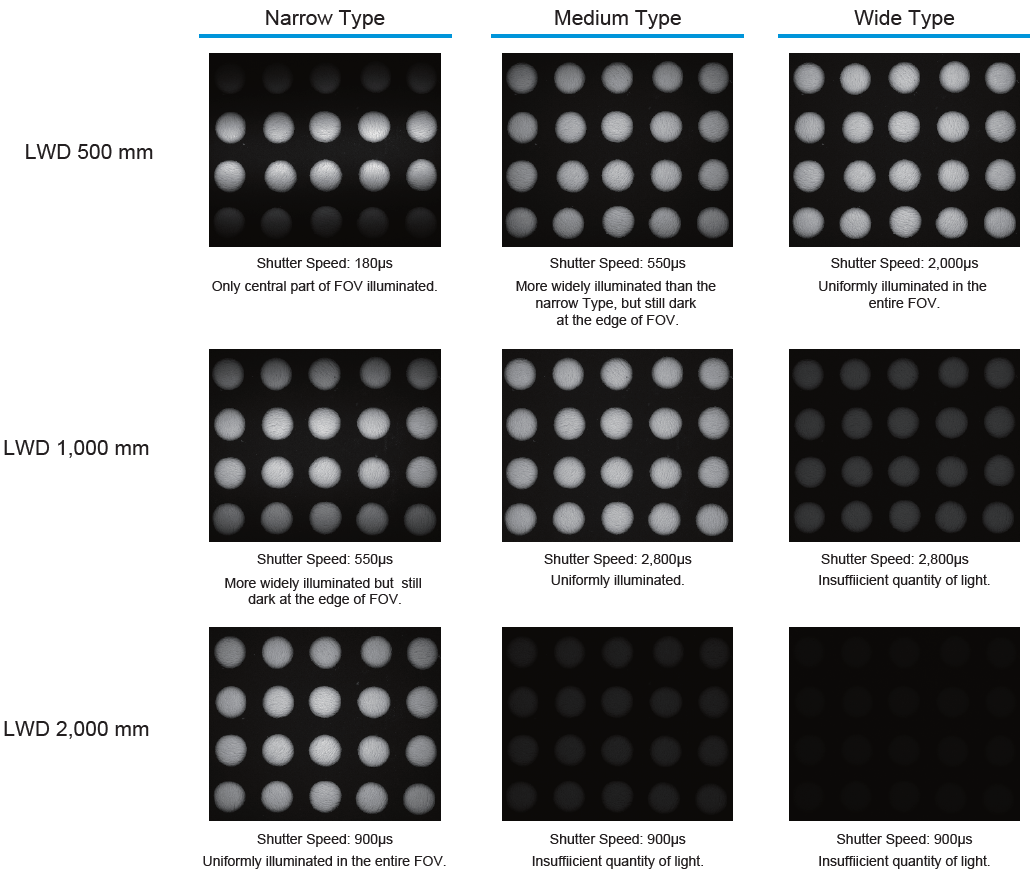

For large FOVs, engineers often prioritize intensity to cover the area, but without the right configuration and position, the result is hot spots or uneven illumination that reduces image consistency. Uniformity across the scene is just as important as brightness.

For long LWDs, the challenge compounds: you need enough intensity to reach the target from far away while still maintaining uniformity. Without proper setup, the result is a dim, low-contrast image, and small defects and critical details can disappear altogether.

Uniformity Is Engineered Through Light Configuration and Setup

Intensity is easy to measure and control, while optimizing uniformity takes careful positioning, diffusion, and sometimes different types of lights. The key to flood lighting is matching your flood lighting to the FOV, working distance, and part surface. These three factors help you determine 1) the uniformity/intensity configuration of the light(s), and 2) the setup of those lights in the system.

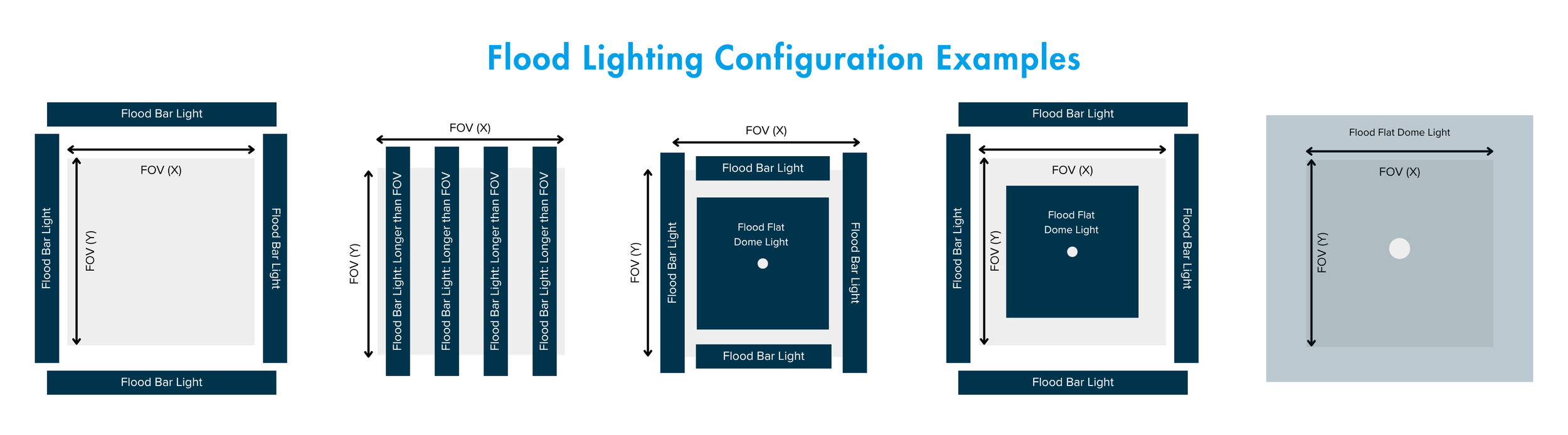

For diffuse, matte surfaces, standard bar lights placed at the edges often provide sufficient coverage. For highly reflective or mirror-like parts, adding a flat dome or increasing the number and angle of flood bars helps eliminate glare and hot spots.

The examples above show how different layouts adapt flood lighting to fit your inspection needs, ensuring clear, consistent imaging without overexposure or dark zones.

Characteristics of Flood Lighting Solutions

Wide-Area Illumination - Since they are meant for applications with larger FOVs, flood lights are designed to maximize area coverage, intensity, and uniformity, with an efficient number of LEDs to keep lights cost-effective.

Quick Adjustment and Setup - Since precise placement of the light is not a limiting factor in flood lighting applications, they are made to easily dial in the right uniformity/intensity to eliminate dark zones or hotspots at a given position.

Simplified Communication - Built-in control for intensity and on/off timing makes flood lights easy to deploy wherever lighting is needed, without the complexity and configuration time required for syncing with external controllers.

— Application Engineer at CCS America

“The flood lighting solution that engineers default to is either 2 bar lights on opposite sides of the workpiece or 4 bar lights on each edge. But it’s usually not that straightforward because the workpiece reflectivity, the FOV, and the LWD determine how uniform the image is. When contrast is already built into the part—like a bold barcode or a large, high-contrast object—the challenge isn’t to create detail, it’s to capture it reliably by minimizing glare and dark zones that can interfere with the target object.”